Fault Tolerance In Cell Installations

Product Support and Customer Service

For Further support visit our Contact Page

General

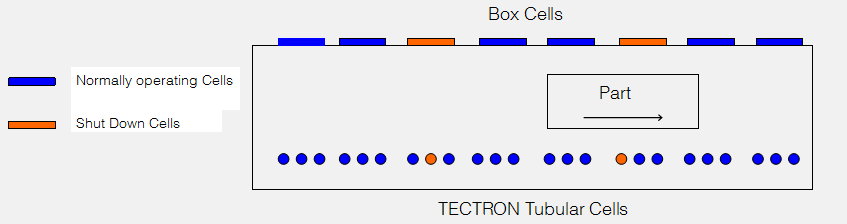

One benefit of having a cylindrically shaped anode cell rather than a box shaped anode cell is increased fault tolerance in your e-coat system. The TECTRON Cell is cylindrical. If one TECTRON Cell is shut down, there is only minimal loss of anode area and minimal stress on the other Cells. If one box anode cell is shut down for electrode or membrane replacement, its absence can cause film build problems. A greater percentage of stress on the remaining boxes creates a domino effect. This can best be illustrated by examining the effect of a shut-down box cell vs. a shut-down TECTRON Cell in a typical e-coat line. In this example, approximately 300 SF of anode area will be required to paint the parts. The anode area is allocated at 150 SF per side, or 11 anode boxes per side vs. 40 TECTRON Cells per side. (See the figure below.) If one box cell is shut down, approximately 10% of the anode area on that side becomes ineffective. If two boxes are down at the same time, 19% of the anode area becomes ineffective. If one TECTRON Cell is shut down, only 2.5% of the anode area on that side of the tank becomes ineffective. In addition, a TECTRON Cell can be replaced in less than 10 minutes, without lifting equipment. A box cell requires up to two hours and three persons to replace.

Conclusion

Anode cells can and do fail. Minimizing the effect of cell failure means the difference between scrapping parts, expensive and time-consuming sanding and rework verses simple anode cell replacement.

Conductivity Sensor & Controller

The Sensor & Controller probably will need to be changed as conductivity levels have increased. As a standard, UFS Corporation only stocks 0-10,000 microSiemens/cm controllers. Another design change is to install the sensor in the pump discharge line to keep it cleaner.

Local Piping

If your pump will be upgraded, you will also need to increase the size of your discharge piping. At a minimum, the discharge piping needs to be 50 mm (2”). Large ED systems can use 75 mm (3”) pipe. The maximum flow velocity should not exceed 2.15 m/sec (7 ft/sec).

Membrane Electrode Cells

Typically, it may take up to five or six TECTRON Cells to replace a box cell or 2 to 3 TECTRON Cells for each crescent-shaped cell. For a complete technical discussion of the TECTRON Cell and its typical installation, request Bulletin #991001 TECTRON Anode Cell.

Electrical Bus

A DC rectifier is an important part of the ED system. The output of the rectifier is fed to the ED tank via a copper bus bar or individual leads. New cells are easily connected to a copper bus bar. On the other hand, if there is a cable for each old box/crescent cell, make sure to attach a copper set screw lug and use a star distribution pattern to the group of TECTRON Cells replacing it.

ITEMS SUPPLIED BY OTHERS

Generally, there is at least $1,000 to $2,000 in replacement parts and materials required. Your Sales & Service Engineer can prepare a pro forma estimate of these materials once your project is defined. Examples of the typical type of materials include : PVC pipe and PVC fittings; 41 mm (1-5/8”) square strut channel; angle iron; etc.

INSTALLATION LABOR

Generally, most end-users use their own maintenance staff to install all the equipment. In some cases, due to time and project constraints, they use a local contractor. UFSc can recommend third party vendors that are experienced with ED paint finishing systems retro-fits. UFSc can estimate labor for the project so you can develop a labor budget. Hours are estimated by trade: millwright, pipe fitter, electrician, etc.

DRAWINGS/DOCUMENTATION

UFSc supplies each retrofit customer with a Cell layout drawing. In addition, UFSc supplies typical General Arrangement drawings for mechanical, electrical, and piping. Your Sales & Service Engineer can assist you with choices and work with you to finalize a design. All the drawings and assistance are at no extra cost.

ON-SITE INSTALLATION

Generally, your Sales Engineer will be present at some point during the installation. The purpose of this visit is to answer questions and ensure the project is moving in the right direction. This on-site service is generally free, but in some cases, it will be quoted at $500 per day plus customary travel, lodging, and meal expenses. Each Sales Engineer carries a pager and can be paged 24 hours a day, 7 days a week.

BULLETIN 991010