Anolyte Color Evaluation

Product Support and Customer Service

For Further support visit our Contact Page

Safety

Think and act in a safe manner. Always disconnect power and use a lockout before you work on the E-coat system, or any of the related subsystems. Observe any confined space conditions. Use the appropriate safety equipment and clothing for the task. Please carefully read all the instructions listed below to familiarize yourself with the project before attempting to perform any of the work.

Required Materials

- Daily Log Sheet

Required Tools

- None

General

Anolyte color is a valuable preventive maintenance tool in an e-coat system. Anolyte flows through each Cell and the anolyte system itself, so its color is often an early indication of a problem. By regularly observing and recording the color of an e-coat system’s anolyte, an e-coat tender can keep the Anode Cells operating at peak performance.

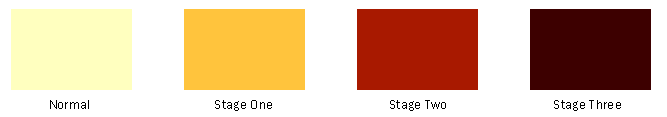

The color chart below has a range from a clear, light yellow color (“normal”) to a dark color, similar to coffee. Your anolyte color will be somewhere within this range. Compare your daily anolyte sample to the color chart and record the color on your daily log sheet. The color should always be “normal”. The pale yellow color at the left or the slight darker yellow (Stage One) is typical anolyte color. If anolyte begins to turn darker, yellowier, or reddish, that is generally an indication of iron particles in your anolyte system. This is an early warning sign of rapid electrode deterioration. The darker your anolyte is, the greater the amount of erosion. If you notice a change, contact your UFSc Sales and Service Representative for a consultation immediately.

Some problems that anolyte color can indicate are listed here. This list is not exhaustive, and should be used only as a tool to help you use anolyte color to predict problems.

- If your anolyte color is Cloudy or Opaque:

- Cut Membrane Shell

- Biological Contamination

- Overspray or splash from the paint tank

- If your anolyte color is Paint Colored:

- Cut Membrane Shell

- Overspray or splash from the paint tank

- If your anolyte color is Clear and Dark Colored, similar to coffee:

- Rapid deterioration of stainless steel anodes. (Refer to the color chart below.) This can be from a variety of causes, such as low flow, high anolyte conductivity, contaminants in the paint bath, etc.

- Quick Change in Anolyte Color:

- Rapid change in color (in any way) can be indicative of a problem. NOTE: TECTRON Cells with non-stainless Anodes generally have a crystal clear anolyte color.